Our company

For more than 20 years, EPM (E stands for Engineering, P for Production and M for Management) cooperates with the automotive industry around the world to respond in an efficient and high-speed way.

Engineering - Production - Management -

Engineering - Production - Management -

Engineering - Production - Management -

Engineering - Production - Management -

Engineering - Production - Management -

Engineering - Production - Management -

Our company

For more than 20 years, EPM (E stands for Engineering, P for Production and M for Management) cooperates with the automotive industry around the world to respond in an efficient and high-speed way.

We help Top Auto Manufacturers suppliers and OEMs Deliver on Launch, Operation and Lean Production. Optimization and competitiveness are part of our DNA that enables us to maintain the highest levels in all areas of the company and this industry. Our focus is to increase the efficiency, launch faster and reduce costs, which leads to an increase of profitability and continuous improvement systems.

With more than 42 consultants, our team includes engineers, researchers, and other skilled employees responsible for product development engineering and manufacturing.

About us

Who we are

We help Top Auto Manufacturers suppliers and OEMs Deliver on Launch, Operation and Lean Production. Optimization and competitiveness are part of our DNA that enables us to maintain the highest levels in all areas of the company and this industry. Our focus is to increase the efficiency, launch faster and reduce costs, which leads to an increase of profitability and continuous improvement systems.

With more than 42 consultants, our team includes engineers, researchers, and other skilled employees responsible for product development engineering and manufacturing.

With more than 42 consultants, our team includes engineers, researchers, and other skilled employees responsible for product development engineering and manufacturing.

Our focus...increase the efficiencylaunch fasterreduce cost increase the profitability

We work under top class rules - IATF, VDA, TPS, etc.

Delivery to achieve PPAP of wide range of OEMs.

Agile / Scrum / Sprint for task forces and processes

Continuous improvement systems: Yamazumi, Kaizen

Our focus...increase the efficiencylaunch fasterreduce cost increase the profitability

We work under top class rules - IATF, VDA, TPS

Delivery to achieve PPAP of wide range of OEMs

Agile / Scrum for task forces and processes

Continuous improvement systems: Yamazumi, Kaizen

0

Years of experience

0

Implemented projects

0

Consultants

0

Offices

0

Working languages

0

Countries served

Some examples of our impact

An EPM launch team provides the interdisciplinary for the challenges from the start of development to successful series production, including process industrialization, plant transformation into AV & EV technology, cost reduction, performance optimization, development, increase efficiency, revenue & profit, performance monitoring, production, quality, purchasing and logistic.

Engineering project management to implement

Automotive Exterior Systems

- € 8M savings

- Deliver 6 months ahead of schedule

- € 8M savings

- Deliver 6 months ahead of schedule

Lean production KanBan integration

Automotive Interior & Exterior Systems

- 2h tact time reduction

- x3 # of cars in same line

- 2h tact time reduction

- x3 # of cars in same line

Support for 0% waste manufacturing concept

Process change to automotive alike TPS method

- 20% increase in efficiency

- One piece flow

- 20% increase in efficiency

- One piece flow

Exhaust system throughput increase

Interim management new plant - industrialization, relocation

- Increase of efficiency, quality

- 15% unit cost improvement

- Increase of efficiency, quality

- 15% unit cost improvement

Some examples of our impact

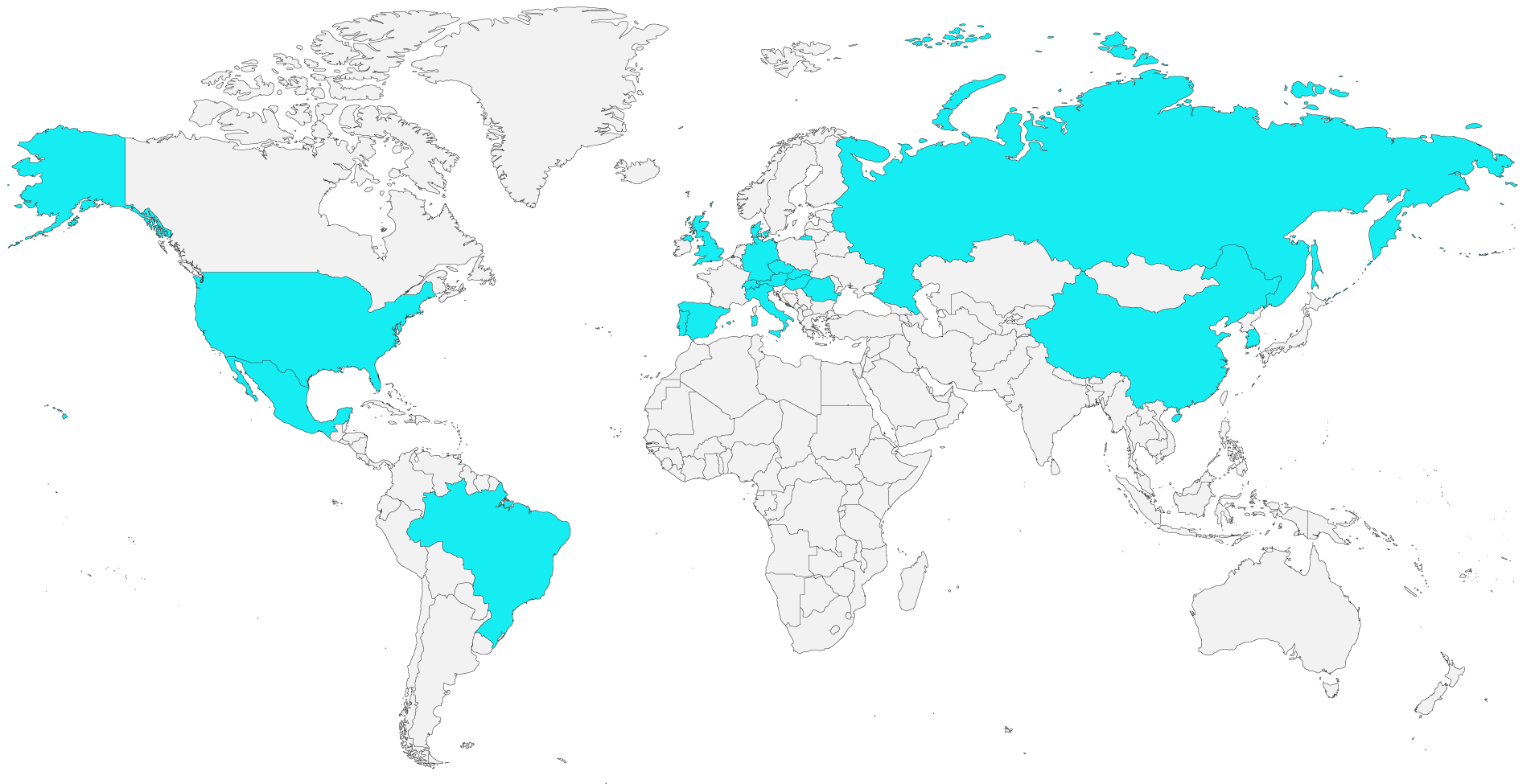

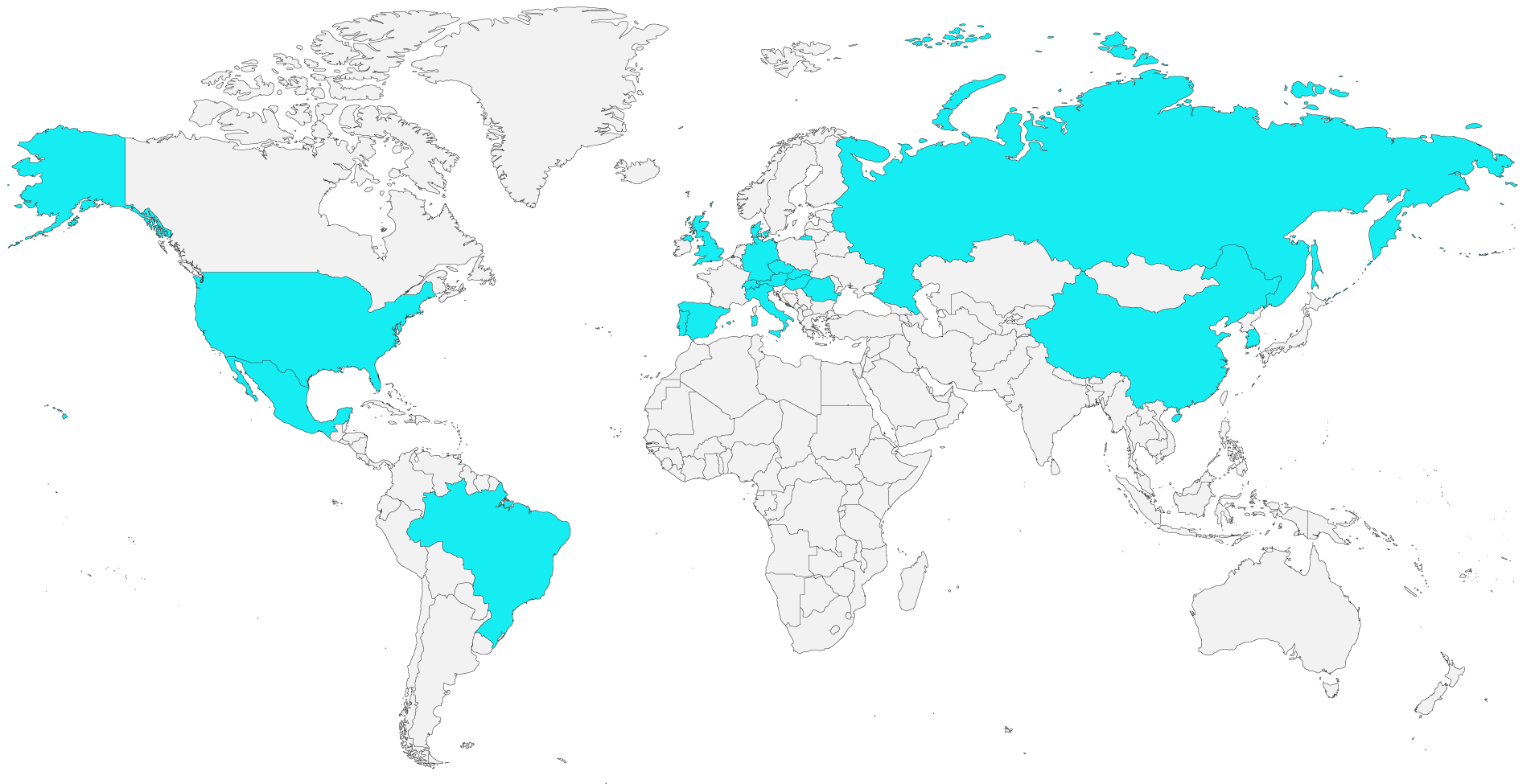

We work alongside with our clients across 18 countries in 3 continents (Europe, America, Asia), where EPM has successfully delivered impact locally and our success is measured by the success of our clients.

Engineering project management to implement

Automotive Exterior Systems

- € 8M savings

- Deliver 6 months ahead of schedule

- € 8M savings

- Deliver 6 months ahead of schedule

Lean production KanBan integration

Automotive Interior & Exterior Systems

- 2h tact time reduction

- x3 # of cars in same line

- 2h tact time reduction

- x3 # of cars in same line

Support for 0% waste manufacturing concept

Process change to automotive alike TPS method

- 20% increase in efficiency

- One piece flow

- 20% increase in efficiency

- One piece flow

Reference regions

Europe

Germany

Switzerland

Austria

Hungary

Romania

Spain

Portugal

Great Britain

Denmark

Czech Republic

Slovakia

Italy

Switzerland

Austria

Hungary

Romania

Spain

Portugal

Great Britain

Denmark

Czech Republic

Slovakia

Italy

America

USA

Mexico

Brazil

Mexico

Brazil

Asia

Russia

China

South Korea

China

South Korea

Reference regions

Europe

Germany

Switzerland

Austria

Hungary

Romania

Spain

Portugal

Great Britain

Denmark

Czech Republic

Slovakia

Italy

Switzerland

Austria

Hungary

Romania

Spain

Portugal

Great Britain

Denmark

Czech Republic

Slovakia

Italy

America

USA

Mexico

Brazil

Mexico

Brazil

Asia

Russia

China

South Korea

China

South Korea

When to

call us

When to call us

Efficiency and experience in detailed and comprehensive planning are key elements of a successful SOP. Sustainable technical expertise and practical experience are a must. Sustainable technical expertise and practical experience are a must.

- Operational management structure lacks control and efficiency

- To industrialize a plant from layout sketch to turnkey

- Improve capability of processes

- Company throughput not high enough

- Need to integrate new technologies

- Project peaks with top skillset team's requirement

- Efficiency requires process & production balancing

- Automatize your product processes, implement robotics and traceability

- Reduce stock or change to – 1 piece flow

- To industrialize a plant from layout sketch to turnkey

- Improve capability of processes

- Company throughput not high enough

- Need to integrate new technologies

- Project peaks with top skillset team's requirement

- Efficiency requires process & production balancing

- Automatize your product processes, implement robotics and traceability

- Reduce stock or change to – 1 piece flow

When to call us

Efficiency and experience in detailed and comprehensive planning are key elements of a successful SOP. Sustainable technical expertise and practical experience are a must. Sustainable technical expertise and practical experience are a must.

- Operational management structure lacks control and efficiency

- To industrialize a plant from layout sketch to turnkey

- Improve capability of processes

- Company throughput not high enough

- Need to integrate new technologies

- Project peaks with top skillset team's requirement

- Efficiency requires process & production balancing

- Automatize your product processes, implement robotics and traceability

- Reduce stock or change to – 1 piece flow

- To industrialize a plant from layout sketch to turnkey

- Improve capability of processes

- Company throughput not high enough

- Need to integrate new technologies

- Project peaks with top skillset team's requirement

- Efficiency requires process & production balancing

- Automatize your product processes, implement robotics and traceability

- Reduce stock or change to – 1 piece flow

They choose to trust us

The clientele of EPM includes international companies from varied sectors (automotive, metal and plastic processing, pharmaceutical, hygiene and more), though the automotive industry forms the focus of the consulting activities.

They choose to trust us

The clientele of EPM includes international companies from varied sectors (automotive, metal and plastic processing, pharmaceutical, hygiene and more), though the automotive industry forms the focus of the consulting activities.